Successful electrification of Doosan excavators

Focusing on sustainability: How start-up Electric Construction Equipment (E.C.E) is taking e-mobility in the construction industry to the next level

Powered by Webasto batteries & thermal management, the company is converting Doosan excavators to make them emission-free on site.

In 2020, the Dutch company Electric Construction Equipment (E.C.E) began working on its vision of advancing e-mobility in the construction industry. To achieve this goal, the company has since started to convert excavators. Webasto‘s intelligent technology, which is used in the two models available so far, plays a central role in this endeavor.

Tapping into a new market with the emission-free electric excavators

E.C.E was founded at the end of 2020 and is part of Staad, an official importer and distributor of Doosan construction machinery. In the conversion of fuel-powered excavators to electric drive, the focus lies initially on the two models DX165W Electric and DX300LC Electric from Doosan. "Our series production is already up and running and the first excavator has been delivered. The plan for 2022 includes about 40 more machines and demand continues to grow," says Pieter Staadegaard, Managing Director at Staad.

With the on-site emission-free electric excavators, the company is tapping into a new market. Customers are currently subcontractors from the construction industry who rely on the advantages of the machines. In the Netherlands, E.C.E. offers the excavators directly, and across Europe other official Doosan distributors can purchase them for their range.

E.C.E now provides the answer for future emission requirements

E.C.E. has identified several reasons for the move towards a zero-emission construction industry. Firstly, the use of the electrified machines has a positive impact on the environment in terms of sustainability. In addition, the technology is now more advanced. Staadegaard emphasises: "Technically, we can make the change. So why are we all waiting? Unlike the big manufacturers, we are far more flexible as a small company, which is why we are encouraging innovation now."

In addition, the construction industry is increasingly restricted, especially in the Netherlands, where the government is pursuing a comprehensive plan for fewer emissions. This now puts the spotlight on construction companies and those affiliated with the construction industry to adapt and find new ways of working.

"In the Netherlands, we have a big problem with nitrogen in the environment. The levels are very high," Staadegaard explains. "The machines are primarily used in city centres, where nitrogen and fine dust emissions are particularly strictly regulated by law. Therefore, we continue to see that the use of emission-free machines is demanded in government tenders - also in Germany." In this respect, E.C.E's zero-emission electric excavators are an ideal solution.

Moreover, such restrictions do not only exist in the Netherlands, but throughout Europe. The reduction of emissions will be of concern in many countries in the future, which is why a new market for innovative solutions is currently emerging. "With our project, we also support Doosan to accelerate the European market introduction of electric machines”, adds Pieter Staadegaard.

Sustainable concept with exchangeable batteries

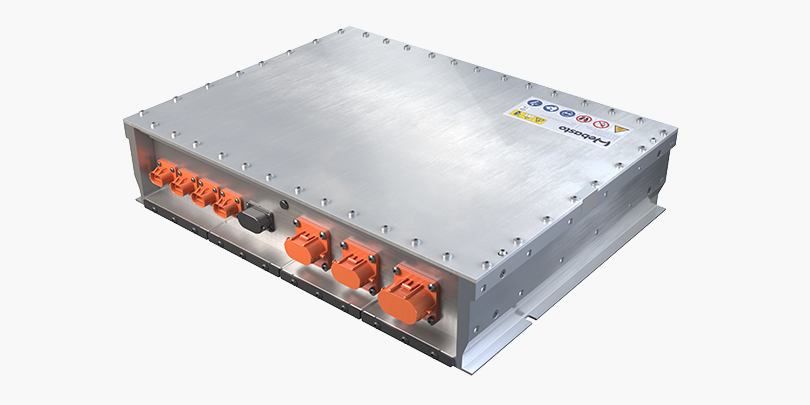

The two excavators from E.C.E. are equipped with Webasto technology at several important points. Webasto supplies standard battery packs for the two models based on E.C.E.'s detailed specifications. The two excavator models DX165W Electric and DX300LC Electric are each equipped with two exchangable powerboxes, each containing 4 CV standard batteries. With each battery providing 35 kWh of power, each powerbox provides 140 kWh of power, bringing the total available power to 280 kWh.

These so called electric powerboxes, form an independent system and are completely developed by E.C.E. with Webasto components inside. They can be removed easily, quickly and recharged elsewhere, as well as being easily interchangeable between different vehicles. Each pack has a self-contained heating and cooling system so that it operates perfectly in all external conditions. Since the battery packs in the system provide a total of 800 volts of voltage, the power loss in transit is reduced and transmission losses are minimised.

Conversion from a single source

The Vehicle Interface Box (VIB) from Webasto plays a decisive role here: in conjunction with the battery system, it enables the necessary communication between the individual hardware components and the corresponding software. In this way, the VIB acts as an efficient interface between several batteries and the vehicle, which combines the functions of a power distributor, battery management system (BMS) and backup system in one robust box.

The BMS is responsible for monitoring and controlling the entire battery system as well as communicating with the other components of the vehicle. In addition to calculating the battery's state of charge (SOC) and state of health, the BMS monitors important parameters such as cell voltages or temperatures and ensures the safe operation of the batteries. The heating and cooling system ensures that the battery does not overheat during the charging process and always maintains the perfect temperature. The result is a comprehensive modular battery system that is optimally tailored for use in commercial vehicles.

Smart charging concept

The concept of the battery-powered excavators is optimally tailored to their use. The ability to replace the batteries means that the excavators' operating time is preserved: "The excavators are available exactly as before, for the entire working day and for a total of eight hours. At the same time, they can perform the same tasks - and do so perfectly at temperatures ranging from - 10 to 35 degrees Celsius," explains Thijs van Hal, Chief Operating Officer at E.C.E.

Webasto’s CV standard battery enabled E.C.E. to develop the interchangeable electric powerboxes. Customers have the option of bringing them to a charging point and recharging them there. This helps if there aren’t charging capabilities on a construction site or in a countryside location. The batteries can each be charged via a type II high-voltage connector, which promises a high degree of flexibility, as the type II connector has now become the standard in Europe. This means that commercial vehicles can be charged safely and quickly at almost any location.

In addition, the vehicles meet the high requirements of the UN/ECE-R100 standard. This European directive defines safety requirements for electric vehicles, such as the minimum insulation resistance of HV components and cables as well as thermal, mechanical, and electrical battery testing.

Close cooperation between E.C.E and Webasto

One of the major challenges of the project was to accommodate all the components of a single battery pack in one box. Webasto actively supported the development, as Staadegaard reports: "Our contacts at Webasto supported us with their battery know-how from the very beginning and thus considerably shortened our development time. In initial tests, batteries did not work at high temperatures. Together with Webasto, we quickly found a solution. And we will continue to share ideas in the future."

The decision to choose Webasto as a partner was also made because of their direct proximity to each other. Especially in view of the Covid 19 pandemic and the associated challenges for the supply chains, Webasto as a local partner was able to provide the products efficiently and reliably.

"We can also rely on the support that Webasto offers us and our customers throughout Europe. Webasto is always located directly on site, has extensive knowledge, knows the machines and can therefore provide fast assistance," adds Thijs van Hal. Especially with the many processes that are interlinked on a construction site, it is essential to minimise downtime, which is why support like this pays off.

More projects ahead

A plan for further projects is already in place. E.C.E is pursuing a holistic approach. "In the long term, we aim to electrify all vehicles that are used on a construction site. In addition, the battery packs will also serve as a replacement for generators in the future, which will then supply power to electric tools for example," explains Thijs van Hal.

In any case, the battery packs will also be in the other commercial vehicles, which will make it easy to exchange them between all vehicles. In the future, E.C.E wants to provide its customers with a broad portfolio of commercial vehicles - from electric sweepers to electric vibratory plates. But regardless of which project comes next, Webasto remains involved as a partner.